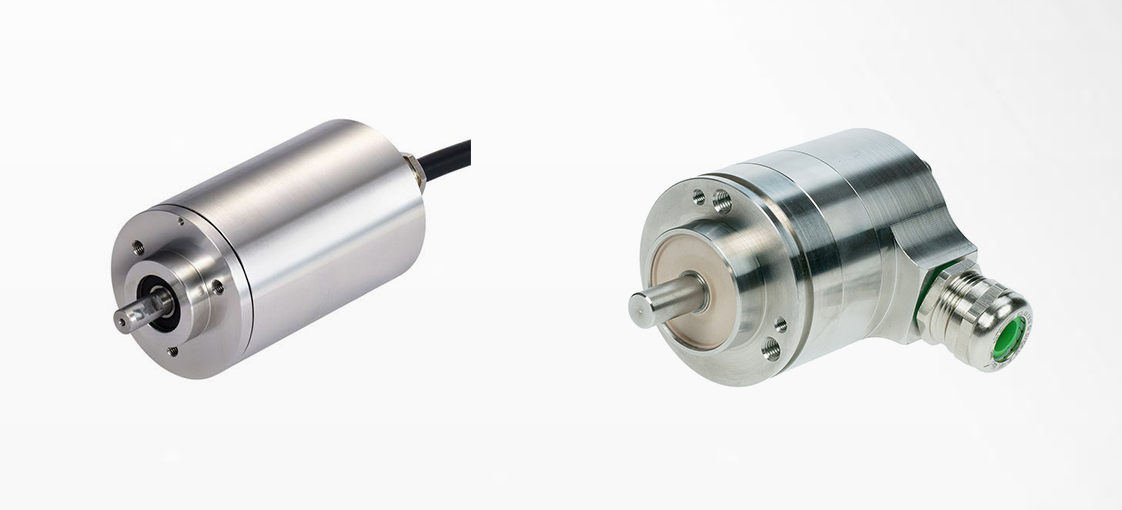

Encoders

| Image | Model | Specification | Application | DataSheet | ||

|---|---|---|---|---|---|---|

|

Incremental Encoders |

|

From cost-aware standard types through to extremely robust heavy-duty products, HENGSTLER can supply the right incremental encoder for every application. With optical incremental encoders, a line-coded disc made of metal, plastic or glass and mounted on a rotary bearing interrupts a beam of light from a light-emitting diode. The number of lines determines the resolution, i.e. the number of measured points in one revolution. The interruptions of the light beam are sensed by the receptor element and electronically processed. The information is then made available as a rectangular signal at the encoder output. HENGSTLER can provide rotary encoders with up to 10,000 pulses per revolution. | Download | ||

|

Absolute Encoders |

|

HENGSTLER's ACURO absolute rotary encoders offer innovative engineering, easy operation and optimised functional dependability. The platform-based concept enables particularly compact construction and modular internal components. As a result of this sophisticated modular system, HENGSTLER is in a position always to provide the right variant for applications involving motor feedback and automation. Equipped with an open BiSS sensor interface, these rotary encoders are ideal for all requirements and prepared for the future. | Download | ||

|

Sin - Cos Encoders |

|

Accurate sinewave rotary encoders by HENGSTLER are a preferred choice in drives with high dynamics thanks to their low harmonic distortion. They have excellent immunity to interference and high functional dependability due to control and system monitoring. The broad working temperature range means the motor can be used to capacity more effectively. | Download | ||

|

Heavy duty Encoders |

|

Download | |||

|

Explosion Proof Incremental & Absolute Encoders | Servo Motor feedback Encoders | Light Duty Encoders | Download | ||

|

Resolvers |

|

Brushless resolvers are the ideal rotor position indicators for the position feedback of brushless motors, robots or direct drives. They are robust, reliable and suitable for high operating temperatures until 155 °C and resistant to most process liquids, contaminations, radiation and EMC-Interferences as well as highly shock-proof and vibration-resistant. | Download |

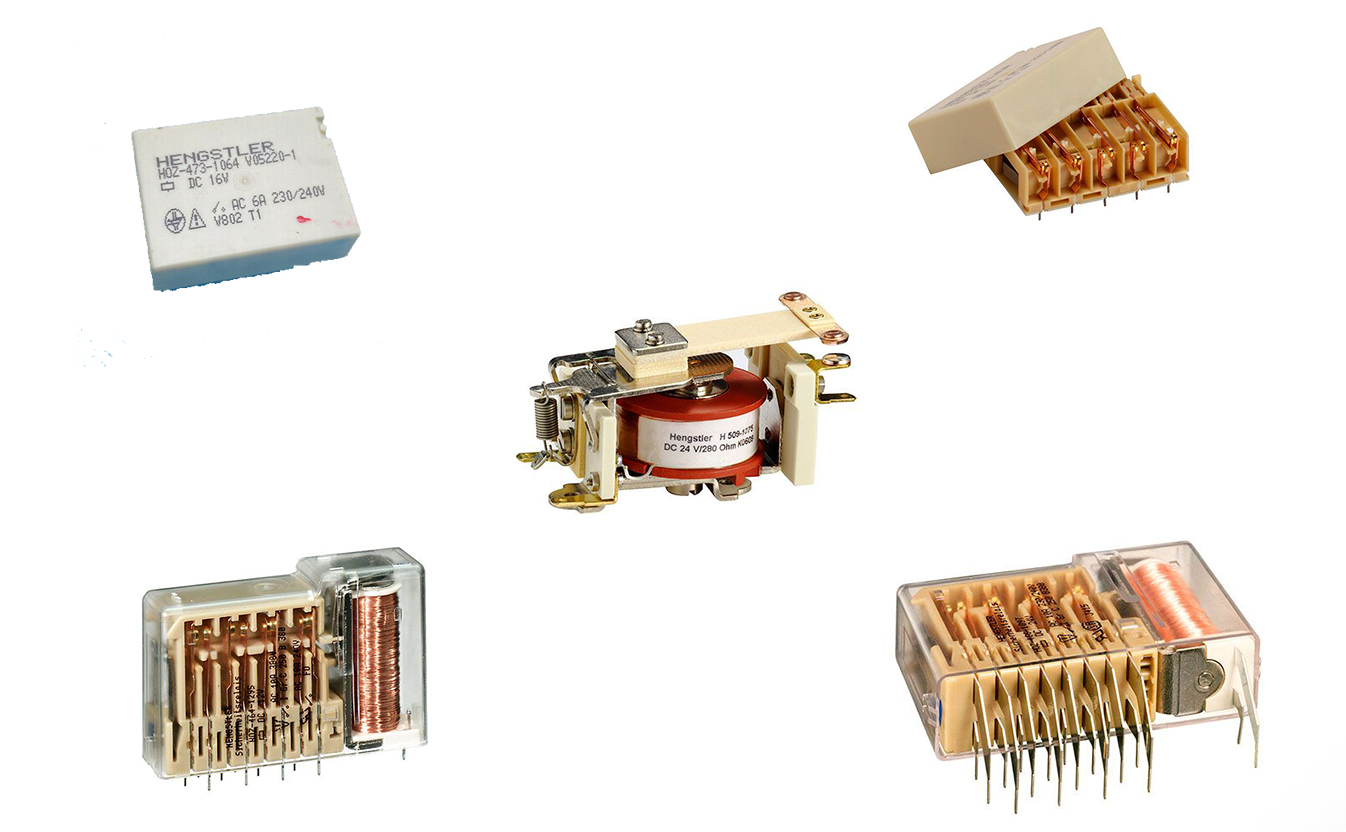

Relays

| Image | Model | Specification | Application | Data sheet |

|---|---|---|---|---|

|

|

|

COUNTERS

| Image | Model | Specification | Application |

|---|---|---|---|

|

|

|

Servo

| Image | Model | Specification | Application |

|---|---|---|---|

|

Modularized Hardware Structure, Highly Integrated Software | Max. I/O points: DIO: Max. 4,352 points AIO: Max. 544 channels RIO>100,000 points |

Large Scale Industrial Machines The AH500 supports excellent motion control functions including 3-axis linear interpolation, 2-axis arc interpolation, and 3-axis helical interpolation. The AH500 satisfies requirements for complex processing or precise motion control and is effective for applications such as building material processors, warp knitting machines and food packaging machines. |

Servo Press

| Image | Model | Specification | Application |

|---|---|---|---|

|

Modularized Hardware Structure, Highly Integrated Software | Max. I/O points: DIO: Max. 4,352 points AIO: Max. 544 channels RIO>100,000 points |

Large Scale Industrial Machines The AH500 supports excellent motion control functions including 3-axis linear interpolation, 2-axis arc interpolation, and 3-axis helical interpolation. The AH500 satisfies requirements for complex processing or precise motion control and is effective for applications such as building material processors, warp knitting machines and food packaging machines. |